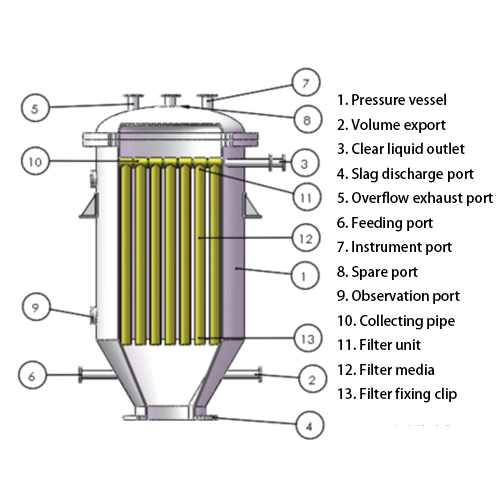

Closed Candle Filter

Those pipes set up inside the filter is functional in different situation. Our candle filer is able to cope with large filter area as no driving equipment and the simple mechanism. This filer is a fully automatic machine without any leakage.

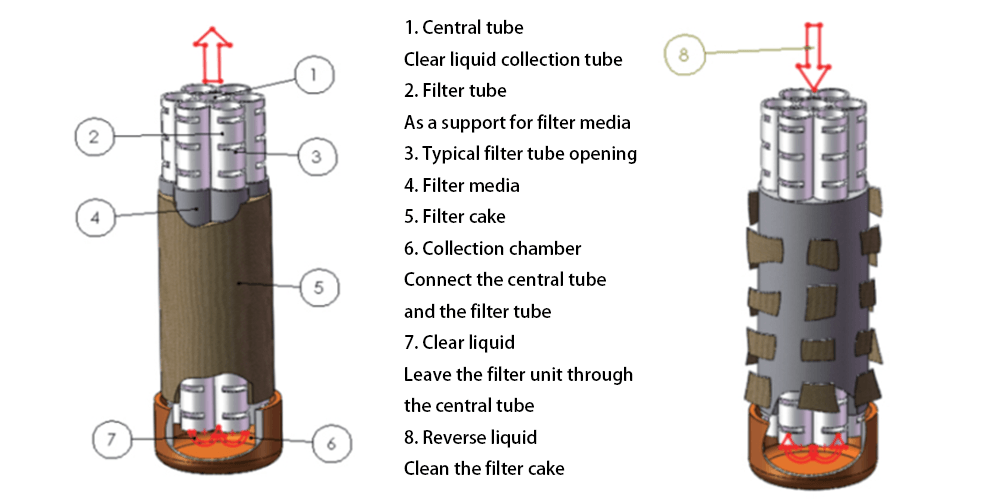

This candle filter is designed in a compound quincunx and row pipe(stainless steel inside,filter cloth outside), the drain pipe in-middle can help drain the liquid kept in the filter pipe, when slag is discharged, the gas is used to blow back, the efficiency is much higher than other filters. This filter can be used in those materiels with the impurity content from 0.1% to 50%.

Product Features:

1. The porous candle filter element with a detachable connection way is easy to change, clean, and maintain.

2. After filtering, the water content of the slag can be adjusted according to customers’ requirements, the filter cake can be crushed easily, then send to the Hollander tub directly, no transporter required.

3. The full-closed operation can be applied to the normal materials, also the special materials which are inflammable, explosive, poisonous, and the machine is available for the filtering of the no pollution fresh food, biologicals, medicines industries.

4. The intelligent control system can save labor costs greatly.

Operating Process:

When the candle filter works, the materials will be send into the filter through the pump, the liquid in the materials will get into the center of the element after the filtering medium, gathering in the purified outlet, then discharged. Before the filter cake formed, the “purified liquid”can be filtered periodically, until the filter cake formed(can meet the filtration requirements), the the signal will be send to stop the circle operation, the purified liquid go to the next normal filter process through the valve.

After normal filtration for a period time, the filter cake reaches a certain thickness, feed charge door closed automatically, after the slag discharged completely, signal will be send by the system to blow back the gas to make the filter cake fall off. After blow-back, slag discharge outlet will be open to start deslagging. Outlet will be closed after going through this whole process. Then return to its initial state, ready for next filtraion.

Filter Sleeve for Candle Filter:

Type: seamless tube

Diameter: 70 & 90mm

Length: 1590 & 1830& 2670 ( can be customized)

Model | Material | Weave method | Weight( g/㎡) | AP( L/㎡s 125pa) | Thickness(mm) |

PCD10P | PP | Plain | 368 | 12.5 | 0.72 |

PCD120T | PP | Twill | 420 | 100 | 0.82 |

PCD03P | PP | Plain | 430 | 3 | 0.71 |

PCD18PB | PP | Plain | 390 | 22 | 0.76 |

TCD20P | PE | Plain | 460 | 18 | 0.65 |

TCD240SDFB | PE | Satin | 225 | 289 | 0.3 |

PPSCD10P | PPS | Plain | 380 | 10 | 0.75 |

PPSCD20T | PPS | Twill | 420 | 25 | 0.85 |

PEEKCD10P | PEEK | Plain | 390 | 12.5 | 0.79 |

PTFECD25 | PTFE | Plain | 550 | 25.8 | 0.41 |

Application:

Biopharmaceuticals: Fermentation extracts, antibiotics, anti-cantharidin, streptomyces, citric acid

Chemical industry: Amine, Catalyst Recovery, Sulfuric Acid, Polyols, Titanium Dioxide, PTA Particles, Polyglycol, Potassium Carbonate

Food and beverage: Apple juice, grape juice, raw syrup, fruit grape syrup, glucose syrup, sucrose, beer, olive oil, palm oil, soybean oil

Metal processing: Cleaning agents, coal tar, machine cooling oil, sheet metal foil rolling oil

Message us

-

Liquid Needle Felt Filter Media

-

-

Liquid Filter Bag

-

Filter Housing

-

- - Single Bag Filter Housing

- - Multi Bag Filter Housing

- - Cartridge Filter Housing

- - Plastic Filter Housing

- - Duplex Bag Filter Housing

- - Beverage Liquid Filter Housing

- - Closed Candle Filter

- - Corrosion Resistant Housing

- - Industrial Bag Filter Housing

- - Multi Cartridge Housing

- - Plastic Housing(Big Blue)

- - Sanitary Housing

- - Single cartridge Housing

-

Liquid Filter Cartridge